By Jessica Domel

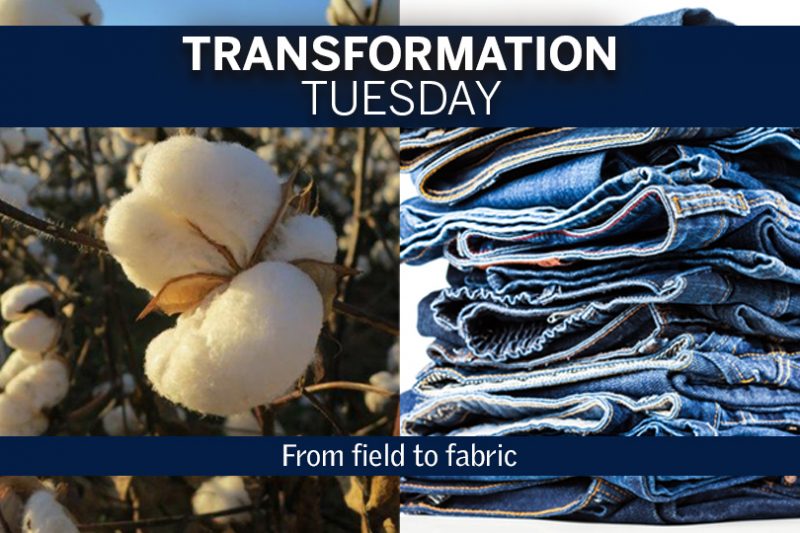

Take a drive through Texas this time of year and you’re bound to find a field or two of white, fluffy cotton.

It’s an economic staple in Texas, and we’re the top cotton-producing state!

Cotton undergoes an amazing transformation to get from fields to our homes.

First, it’s not just used for our favorite fabric.

Cottonseed can be processed into a meal that cattle like to eat.

It can also be used to create a cooking oil. Like potato chips or mayonnaise? Check the ingredients label. Chances are, it has cottonseed oil in it.

Although there are many uses for cotton, it’s perhaps best known for its use in clothing items like T-shirts and blue jeans.

It takes quite a transformation to turn a white, fluffy cotton boll into a soft pair of jeans.

First, the cotton must be stripped or picked out of the field. Both machines, although different, remove the cotton from its woody-like plant in the field.

It’s then rolled into a round bale like hay or it’s formed into a large, loaf-like module to make transporting large quantities of cotton easier.

When cotton modules or bales arrive at a cotton gin, they’re taken apart. The cotton is then dried and cleaned. Cottonseed and the fiber are then mechanically separated.

The seed is then sent on to be processed into oil or meal and used in foods, cosmetics and more.

The fiber then takes an extra journey to a mill where it can be woven into the cloth used to make our sheets, towels and other products.

Fabrics then head to warehouses, shipping companies, textile manufacturers and eventually to retailers where you’ll buy your new favorite shirt.

Did you know: one bale of cotton can make:

- 215 jeans

- 249 bed sheets

- 690 Terry bath towels or

- 1,256 pillow cases.

Texas cotton makes quite a transformation from the fluffy bolls in the field to our favorite clothing, but it’s a process that’s well worth the wait.

I know that the farm bureau works along side the cotton industry. I am an 8th grade history teacher who covers items such as the cotton gin and cotton plantations during the time of slavery. I am looking for samples of cotton, so that I may help my students understand how time consuming and painful cotton harvesting and process were. Do you know of any place where I might get samples of cotton on the stalk, without going into a field and just taking some?

Good evening!

Thank you so much for commenting. I don’t usually recommend just walking into a field and taking a crop. Have you contacted your local county Farm Bureau office? They may know a farmer who is willing to donate some to your classroom? If not, we have an ag education department here that I can put you in touch with.

Jessica

I grew in New Braunfels. Mission Valley Mills and Comal Cottons used to be a major employer. Some of my fellow high school students worked at the mill nights. They had two very large factories. Hopefully, the manufacture of cotton products will return to the USA. On a another note, I have the small sized cotton sack that was made for my mother when she was a child. The whole family was involved in picking cotton, no one else.